-

National consultation hotline:

13590252450 / 18676388050

Time:2024-05-09 Preview:1

Hello everyone, I am the editor. Today I will introduce to you how to choose the third monomer of EPDM. The following content is compiled by the editor, and the relevant content is for reference only.

EPDM or ethylene propylene diene monomer is a terpolymer of ethylene, propylene and non-conjugated dienes. The annual global consumption is 800,000 tons. The main characteristics of EPDM are its superior resistance to oxidation, ozone and corrosion. Since EPDM belongs to the polyolefin family, it has excellent vulcanization characteristics. Among all rubbers, EPDM has the lowest specific gravity. It can absorb a large amount of fillers and oils without affecting the characteristics. Therefore, low-cost rubber compounds can be made.

EPDM is a terpolymer of ethylene, propylene and non-conjugated dienes. Diene has a special structure, only one of the two bonds can be copolymerized, and the unsaturated double bond is mainly used as a crosslink. The other unsaturated will not become the main chain of the polymer, but only a side chain. The main polymer chain of EPDM is fully saturated. This feature makes EPDM resistant to heat, light, oxygen and especially ozone. EPDM is essentially non-polar, resistant to polar solutions and chemicals, has low water absorption, and has good insulation properties.

In the production process of EPDM, its characteristics can be adjusted by changing the number of three monomers, ethylene-propylene ratio, molecular weight and its distribution, and the method of vulcanization.

The selection of the third monomer for EPDM:

The third diene type monomer is produced by copolymerization of ethylene and propylene to produce unsaturation in the polymer in order to achieve vulcanization. The selection of the third monomer must meet the following requirements:

1. A maximum of two bonds: one polymerizable and one vulcanizable;

2. The reaction is similar to the two basic monomers;

3. The main bond is randomly polymerized to produce a uniform distribution;

4. Sufficient volatility to facilitate removal from the polymer;

5. The final polymer has a suitable vulcanization speed.

Currently, there are only three third monomers used in the industrial production of EPDM rubber:

Ethylene norbornene (ENB);

Dicyclopentadiene (DCPD);

1,4-hexadiene (HD).

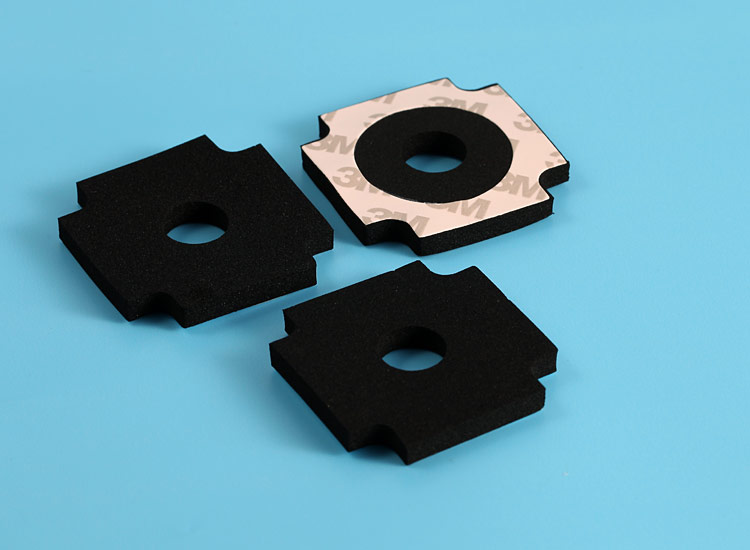

Shenzhen Haoou Sealing Technology Co., Ltd. is a modern enterprise integrating R&D, production and sales. The company's main products are: high temperature resistant sealing rings, sealing rings, perfluororubber, O-rings, fluororubber, conductive silicone, rubber products, food grade silicone, solvent resistant sealing rings ETP, EPDM, acid and alkali resistant sealing rings, EPDM rubber foam, CR rubber foam and other products. Welcome to visit!