-

National consultation hotline:

13590252450 / 18676388050

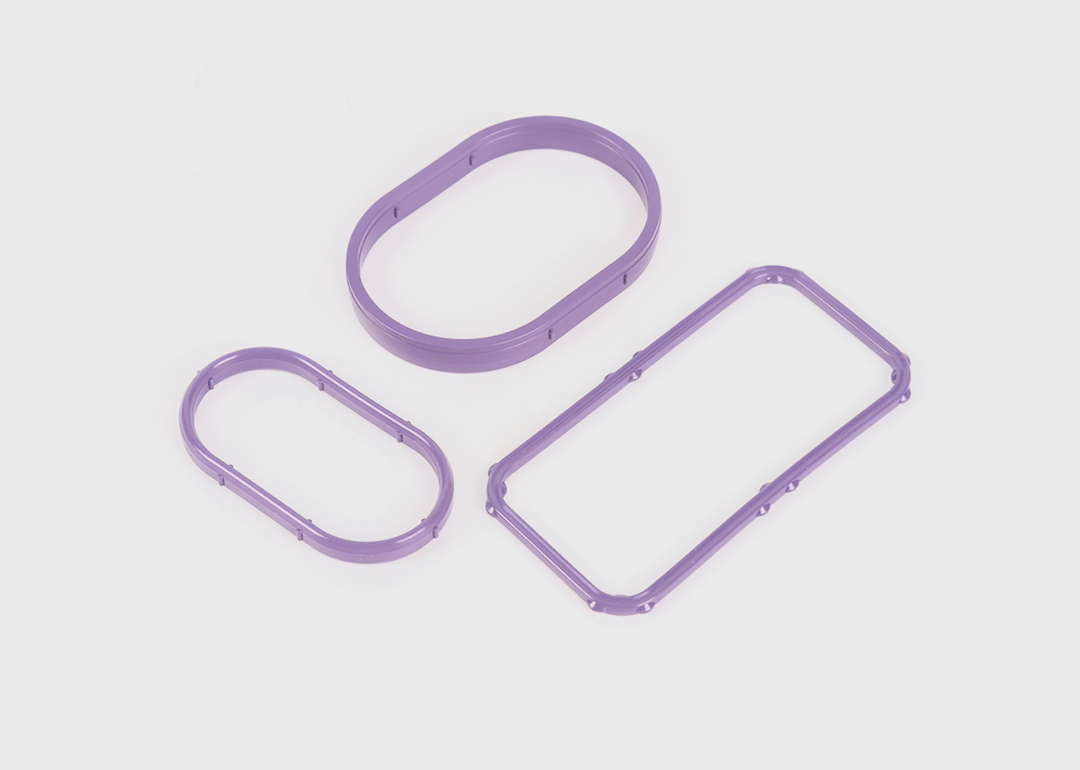

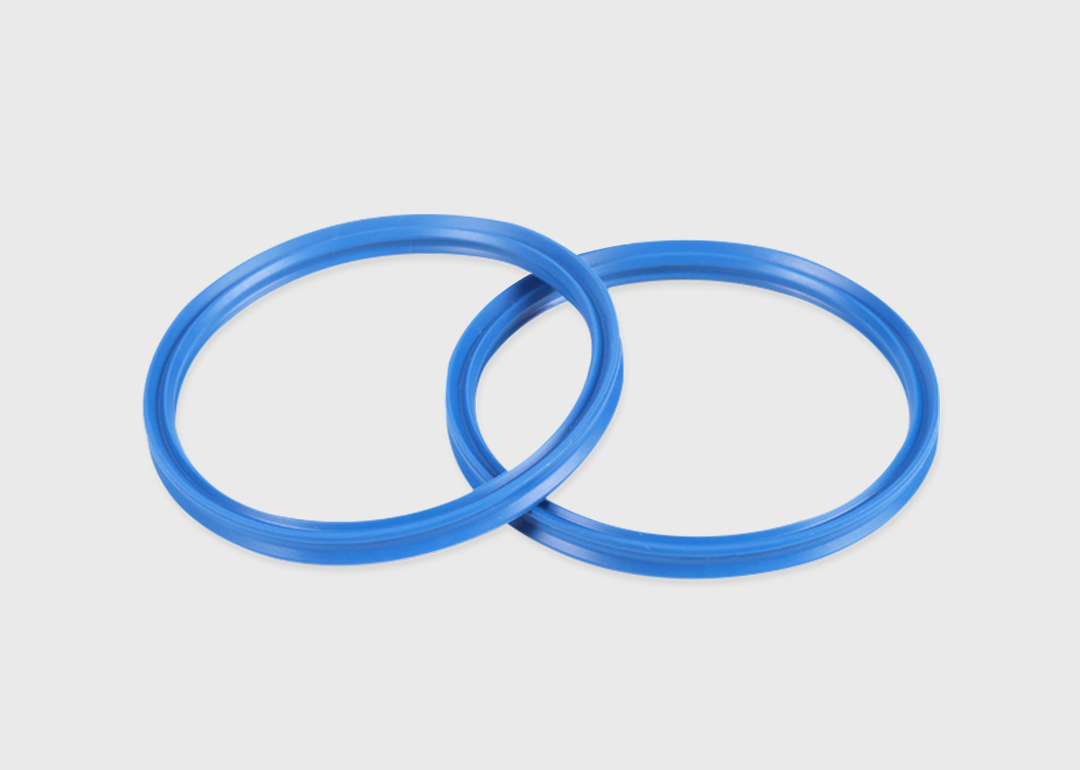

We offer seal rubber products made of NBR, EPDM, HNBR, FKM and other materials.

High temperature resistant FKM: 275°C seal

High temperature resistant FFKM: 350°C seal

High temperature resistant VMQ: 300°C seal

High temperature resistant HNBR: 175°C seal

For the automotive industry: resistant to fuel, gasoline, ethanol gasoline, methanol gasoline, and diesel.

For the chemical industry: resistant to strong acids, alkalis, lithium battery electrolytes, H2S and CH4, solvents, paints, oils, and all kinds of corrosive gases.

Low temperature resistant FKM are:

FKM low temperature TR10 = -30°C, static sealing can reach -40°C

FKM low temperature TR10 = -40℃, static sealing can reach -50°C

FKM low temperature TR10 = -45°C, static sealing can reach -55°C

Our FKM, EPDM, VMO raw materials meet food hygiene requirements, mainly in accordance with

FDA 21CFR 177.2600

NSF61

WRAS

The materials of our semiconductor-grade sealing rings can be basically free of fillers according to user requirements, or only organic materials such as PTFE can be added. We can achieve high-cleanliness and high-purity FKM and FFKM. We do not plan to artificially add substances containing metal ions and generating particles.

Our raw materials include RGD-grade HNBR-90 and FKM-90 materials certified by Element in the UK, which can be made into various sealing products.

We can add wear-resistant components to NBR, EPDM, HNBR, FKM and other materials to improve the wear resistance of the material, while reducing the friction coefficient of the material to avoid sticking and climbing phenomena during dynamic sealing.

Rubber is an insulating material. By adding conductive components, different surface resistivities, or volume resistivity and surface resistance can be obtained. When the surface resistivity of the rubber material is ≤10^3Ω, it is conductive rubber.

The peroxide high-fluorine FKM-GF material is resistant to lithium hexafluorophosphate electrolyte, and the peroxide-sulfurized EPDM material is resistant to electrolytic cell electrolyte.

We can add wear-resistant components to NBR, EPDM, HNBR, FKM and other materials to improve the wear resistance of the material, while reducing the friction coefficient of the material to avoid sticking and climbing phenomena during dynamic sealing.

We can recommend our sealing solutions according to the customer's working conditions, or process various rubber products and metal-rubber bonding products according to drawings.